Water resources management

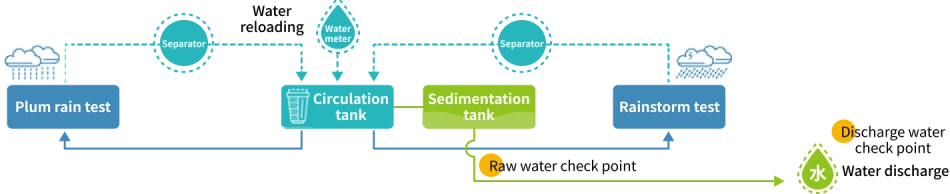

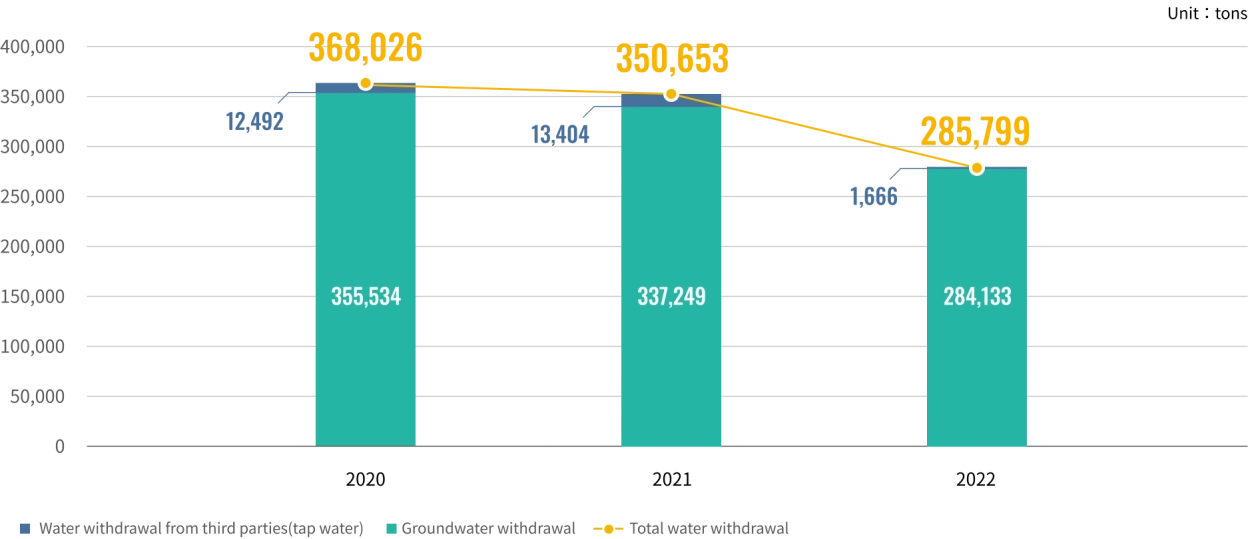

The water used in the primary manufacturing process of Yulon Motor is sourced from the groundwater in the Hsinchu-Miaoli Area promulgated by the Water Resources Agency, and we have confirmed that the operating location in Taiwan is not located in area with high pressure on water resources using the WRI Aqueduct tool. All water used in the plant and the office is supplied from the waterworks of corresponding area while the drinking water is tap water (freshwater). The total groundwater and tap water consumptions in 2022 were 778 CMD (tons/day) and 5 CMD, respectively; the total water consumption in the plant was 783 CMD, a decrease of 127 CMD from 910 CMD from the previous year. The water discharged from the production processes of Yulon Motor is tested in accordance with the environmental laws and regulations, treated by third-party wastewater treatment plants and ultimately discharged to natural body of water. We actively sample and test the soil and groundwater at the plant striving for environmental friendliness and avoiding any negative impact on the community. Based on the groundwater level observed, we can conclude that our use of groundwater has no significant effect on the water source and we did not cause any potential or negative impact on the environment in Sanyi Township. In respect of impact on water resources arising from climate change, we have planned the water restrictions and implemented water resources circulation and reuse. By continuing introducing the process and wastewater recycling and reuse system and tracking water consumption, we ensure a 10% reduction in water usage every year.

Sources, recycling and discharge of water resources in the most recent 3 years

Water withdrawal in the past 3 years

Regular inspections on all pipelines at the plant for leakage control

We conduct regular inspections on all pipelines at the plant for leakage control, draw a water use balancing graph and put forward water-saving measures based on the water usage of each location in addition to the installation of rainwater harvesting system and improvement of recycling rate. With the efforts in both water use and water saving, in 2022, we optimized the water discharge volume of the vehicle leakage test equipment by setting the water discharge frequency to perfection. The discharge volume was reduced to 0.02 ton/vehicle from 0.33 ton/vehicle with a total water saving of 7,750 tons/ year; a total of 30% water is expected to be saved in 2023.

Water resource reduction achievements in 2022

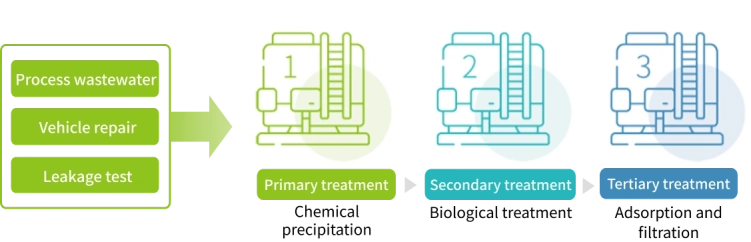

Water Pollution Control

The wastewater and runoff water of the Company are discharged through dedicated pipes. They did not produce significant impact on the water body, habitat environment and biodiversity. The waste coating water discharge by the plant usually contain rich organic pollutants and the monitoring of the water quality focuses mainly on the Chemical Oxygen Demand (COD), Suspended Solid (SS) and heavy metal. The wastewater pollution control measures of the plant aim at reduction of the wastewater at the source and during the process, separate treatment of rainwater and sewage, setup of rainwater retention facilities, expansion and maintenance of existing wastewater treatment systems, and implementation of wastewater recycle. We conduct regular measurement against different water quality indicators and draw a run chart for tracking purpose in order to maintain the best operation status, improve the wastewater treatment efficiency, and achieve the goals of energy saving and carbon reduction. After being treated by the wastewater treatment plant, the process wastewater is tested on a quarterly basis, and the test values in 2022 were 21.5mg/L for chemical oxygen demand (COD) and 0.10mg/L for nickel (Ni), both were way below the limits set forth in the Effluent Standards (COD <100mg/L; Ni <0.7mg/L), so there is no material impact caused by water withdrawal.

Handling procedures at the wastewater treatment plant

Soil and groundwater pollution control strategy

We have taken measures to the underground pipelines and related facilities that may bring about pollution to soil and groundwater, such as the anti-penetration PU, spill dike and oil-water separation devices, to put the principle of“ prevention is better than remediation” into practice. Our control actions include: dedicated ditches for rainwater are set up and separated from the pipelines of wastewater; external service providers are commissioned to sample the groundwater every year to monitor the pollution status at the plant location; trees are planted on the side slope around the plant to avoid loss of soil. Insecticides are prohibited. Please refer to Appendix 7 for the groundwater quality monitoring record of 2022.