Supplier Management

Suppliers are essential to our sustainable development, so by capitalizing our corporate influence, Yulon Motor builds close relations with suppliers in order to have positive impacts on economy, environment and society. In recent years, we have assisted suppliers in obtaining the ISO 14001 certifications in order to encourage them to implement an environmental management plan; meanwhile, with regard to the protection of labors’ human rights, we also include the criterion that whether a supplier meets the requirements of the Labor Standards Act in the supplier selection. All conditions and terms in the agreements with partners in the supply chain are handled and filtered in accordance with national laws related to human rights, or terms and conditions regarding human rights are supplemented.

Regulations for supplier sustainability:

In addition to the signing of the“ Supplier’s Undertaking of Corporate Social Responsibility,” Yulon Motor also added the requirements set forth in the Ethical Corporate Management Best- Practice Principles for TWSE/TPEx Listed Companies in the agreements with suppliers to ensure that suppliers deliver quality products and meet Yulon Motor’s regulations in connection with sustainability.

Supplier Quality Evaluation

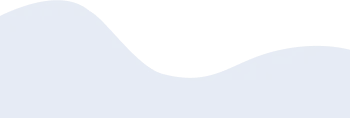

We have carried out evaluations to check a supplier’s performance in incoming materials, delivery, part production management and the operation of its quality management system. Since 2022, the quality improvement supervision project have been proposed to 10 suppliers in total, and in 2022, we guided 3 suppliers in improving their products to the A-grade with a 100% quality improvement project completion rate. We continue to guide suppliers through quality standard enhancement by facilitating events for Quality Assurance Requirements of suppliers’ independent processes and assist key suppliers in conducting QAR self-supervision evaluation. A total of 11 suppliers completed the evaluations in 2022 and established their QAR MAP technology library, thereby enhancing quality of parts and averting reoccurrence of issues; we also guided suppliers through the introduction of the part management system for Supplier Quality Management (SQM) where a total of 31 suppliers improved their rating to B+ with a 100% evaluation rate.

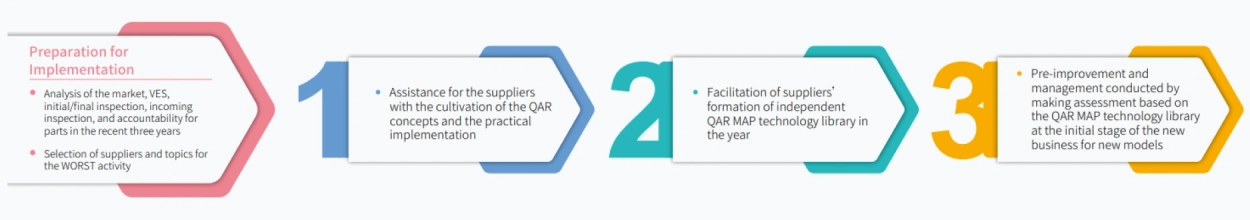

Supplier evaluation process

- To make sure the improvement plan proposed by Yulon’s team is helpful for the supplier in generating actual benefits from improvement

- To go deep with the suppliers to check their approaches to each control

- To find the root of issues and propose mutually beneficial improvement plan

Note: Achievement rate equals to the number of suppliers who were actually evaluated divided by the number of suppliers who shall be evaluated.

We designate a responsible unit for the guidance and supervision of suppliers’ improvements. Multiple effective communication and improvement activities designed for suppliers have been carried out via various channels such as the directors’/supervisors’ meetings and the general meetings of the Yulon Motor Association and corporate seminars covering exchange activities, education and training and visit and learning activities to realize the ideals of“ complementary environmental protection and economic development for co-existence and co-prosperity” and create overall social benefit in the protection of environment. We routinely track the results of improvement plans of suppliers with a low rating score and guide them through the enhancement of performance.

Evaluation of supplier sustainability

We evaluate items in the topics of labor, ethics and environment in detail in the annual evaluation of suppliers and thus facilitate a good understanding of suppliers’ overall sustainability risk and performance.

Yulon Motor has promoted the ongoing supplier sustainability management project as follows:

Environmental, health and safety management of contracting manufacturers

Yulon Motor takes contracting manufacturers’ environmental, safety and health management seriously, so we arrange safety inspections at contracting manufacturers’ sites every year to conduct the on-site examination on three aspects: firefighting safety, environmental protection and safety and health, and keep the improvement plans on file for follow-up. Assisted 8 contract manufacturers in the improvement of 23 environmental, health and safety issues in 2022. On top of the safety inspections, we also exchange information on matters concerning environment, safety and health in the hope of jointly sculpting a corporate culture of occupational safety.